Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Modelo: Airbag System

Marca: htd

Lugar de origen: PORCELANA

Posicionamiento del producto:

El anillo de retención del inflador HTD es el componente crítico de soporte de carga dentro del sistema de bolsa de aire del automóvil, diseñado para anclar de forma segura y precisa el inflador a la estructura de la carrocería del vehículo. Actuando como el "esqueleto estructural" del módulo de bolsa de aire, debe resistir y transferir instantáneamente la tremenda fuerza de reacción del encendido del inflador y las cargas de impacto al marco del vehículo durante una colisión, al mismo tiempo que garantiza la estabilidad posicional absoluta del inflador. Fabricado con aleaciones de acero/aluminio de alta resistencia mediante procesos de estampado/fundición a presión de precisión, logra la integración perfecta de resistencia ultraalta, excelente resistencia a la fatiga, posicionamiento preciso y antiaflojamiento confiable bajo cargas dinámicas extremas, sirviendo como base mecánica para el despliegue oportuno y preciso del sistema de bolsa de aire.

Parámetros clave de rendimiento del estampado :

| Category | Specific Parameters | Test Standard |

| Primary Material | High-Strength Steel (B340LA, HC420/DP600), High-Strength Aluminum Alloy (AlSi10Mg), Custom | Customer Specified / With Material Certificate |

| Static Strength | Tensile Strength ≥ 400 MPa (Steel), ≥ 250 MPa (Al); Yield Strength meets design target | ISO 6892-1 / ASTM E8 |

| Dynamic Performance | Crash Impact Energy Absorption ≥ Specified value; Fatigue Life ≥ 1×10⁶ cycles (load spectrum) | Enterprise Standard / Customer DV Specification |

| Mounting Accuracy | Inflator Mounting Hole Position Tolerance ≤ ±0.2mm; Mounting Surface Flatness ≤ 0.3mm | 3D Dimensional Report / CMM Inspection |

| Torque Performance | Fastener point Torque-Angle Curve compliant; Anti-loosening design, post-vibration torque decay < 15% | ISO 16047 / VW 01103 |

| Corrosion Resistance | Steel: Zinc-Aluminum Coating/Dacromet (≥720h NSS); Aluminum: Anodizing/Micro-arc Oxidation | ISO 9227 Salt Spray Test |

| Process Characteristics | Precision Stamping (Steel) / High-Pressure Die Casting (Al), burr-free in critical areas | VDA 19.1 Cleanliness Control |

| Step | Core Process | Key Technical Points | Output Standard |

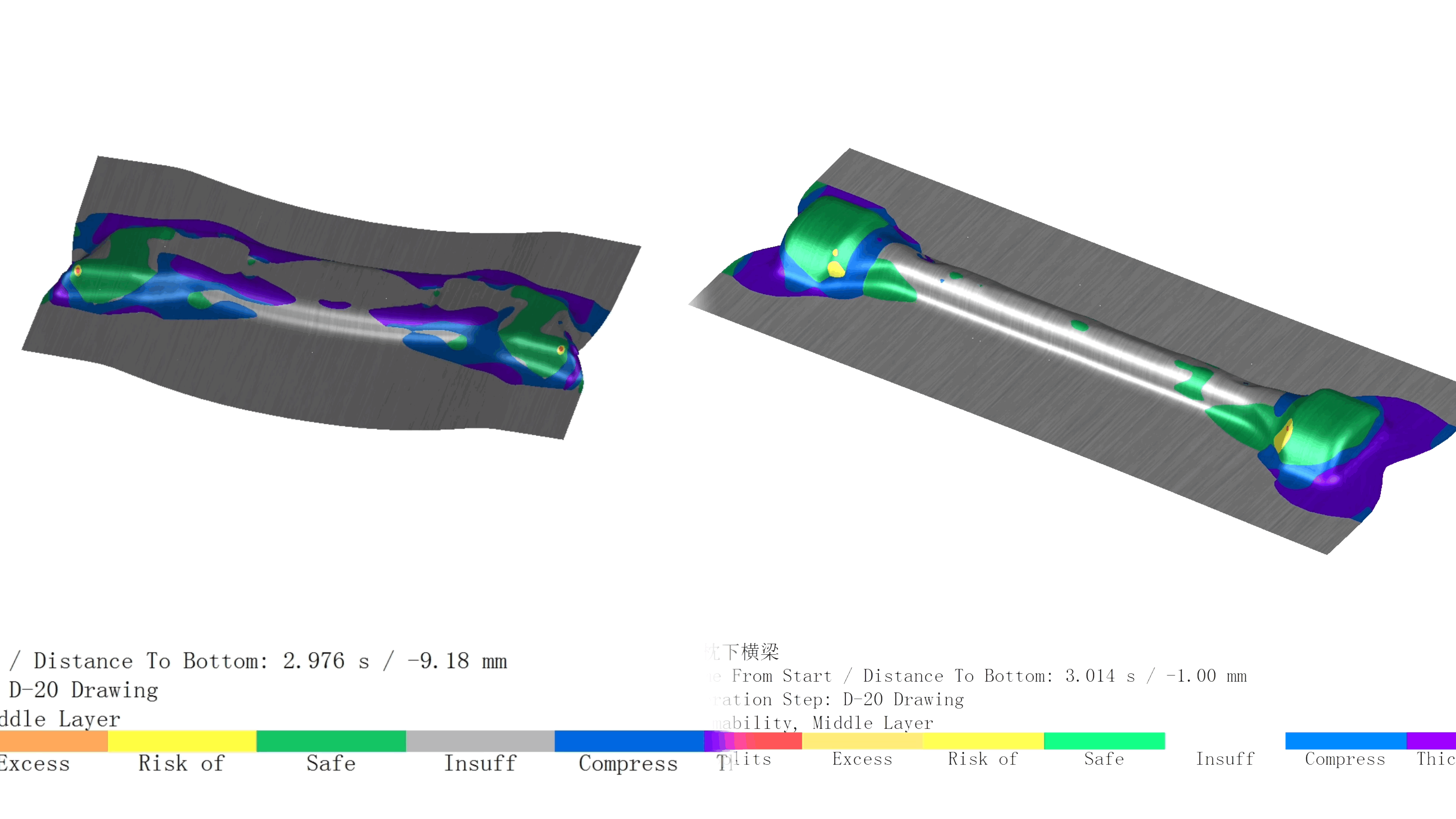

| 1 | Simulation-Driven Design | Multi-disciplinary simulation optimization (Crash, Vibration, Fatigue) | Simulation report approved, safety factor meets target |

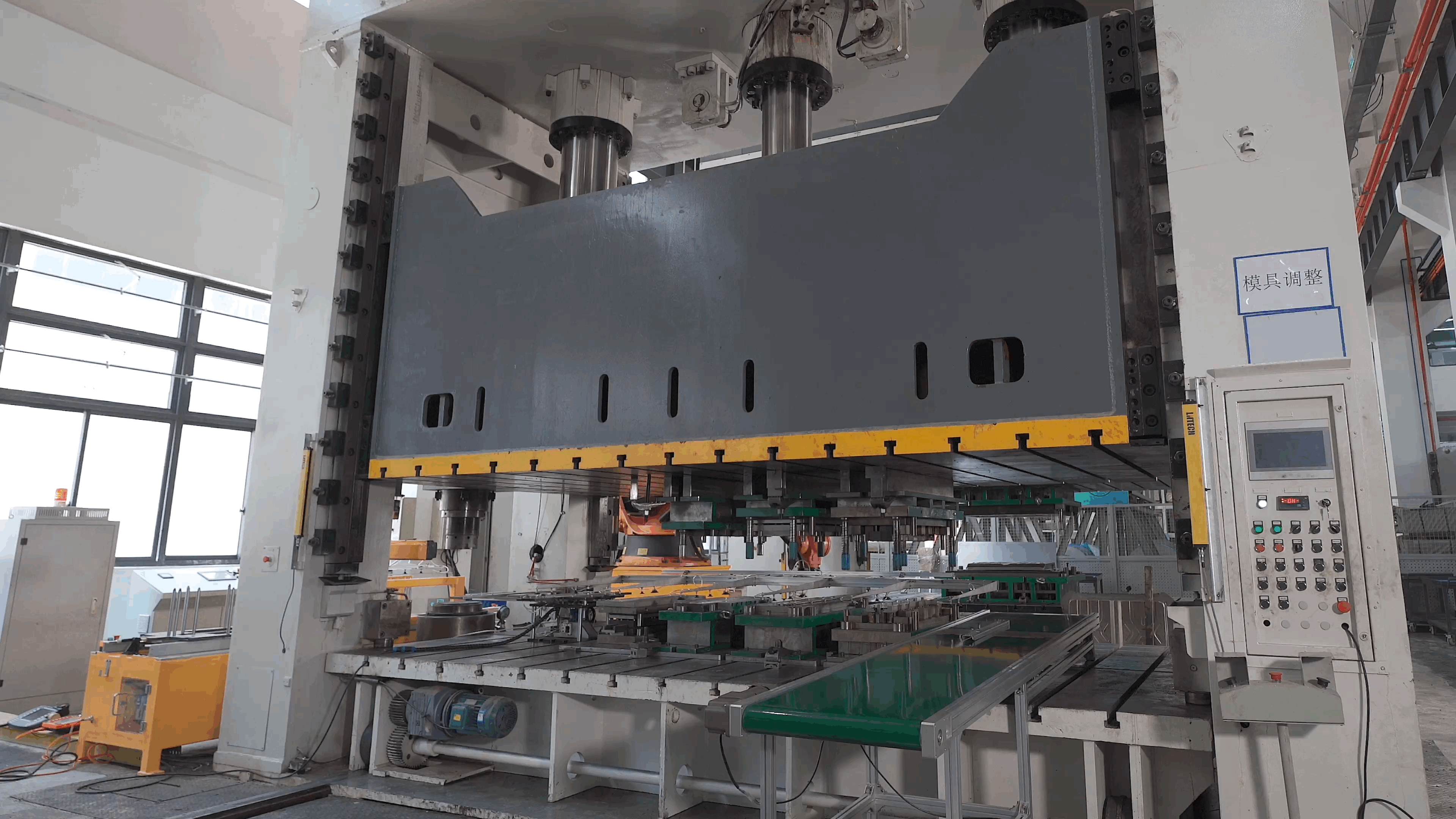

| 2 | Precision Forming | Hot Stamping / High-Vacuum Die Casting, real-time in-mold temperature & pressure monitoring | Material strength and microstructure qualified, free of forming defects |

| 3 | Performance Heat Treatment | Controlled atmosphere continuous furnace heat treatment, closed-loop process control | Mechanical properties (Tensile, Yield, Elongation) 100% meet spec |

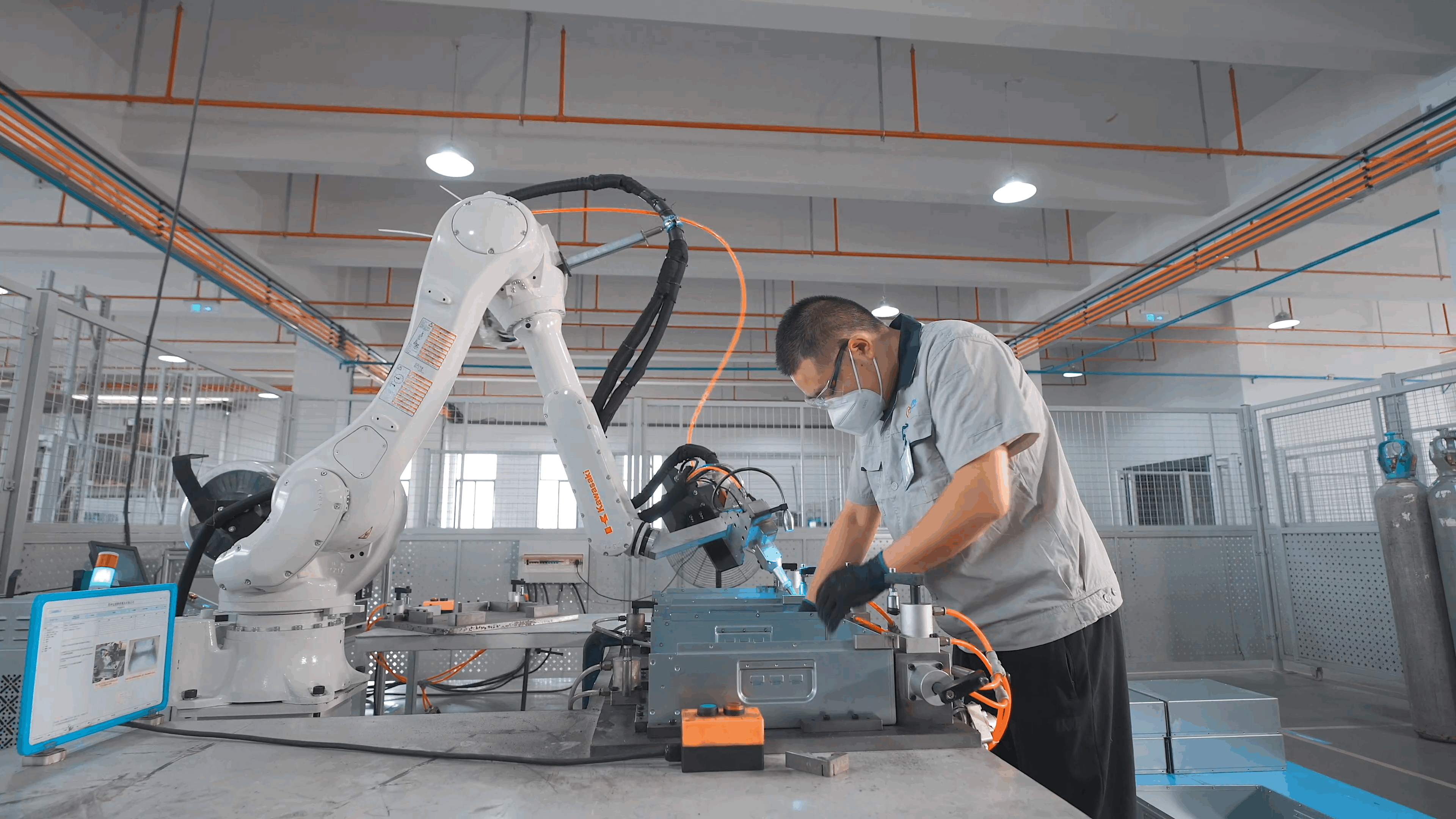

| 4 | Intelligent Finishing | Robot adaptive machining, in-line laser measurement & compensation | Key dimension CPK≥1.67, position tolerance 100% passed |

| 5 | Surface Treatment & Assembly | Eco-friendly coating, clean assembly, 100% optical & torque inspection | Salt spray, coating thickness, assembly torque 100% passed |

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.