Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Modelo: Electric Control System

Marca: htd

Lugar de origen: PORCELANA

Posicionamiento del producto:

La barra colectora de la unidad de distribución de alto voltaje HTD es el componente conductor central integrado dentro de la unidad de distribución de energía (PDU/BDU) responsable de la distribución, conversión y protección de la energía eléctrica. Actuando como "esqueleto" y "vasos sanguíneos" del sistema de distribución de energía, recolecta alta corriente del circuito principal y, a través de su diseño integrado de múltiples ramas, distribuye energía de manera precisa y confiable a varios subcircuitos. Utilizando aleaciones de cobre/aluminio altamente conductoras y tecnología de moldeo por inserción, logra el equilibrio perfecto entre baja impedancia, alta capacidad de transporte de corriente, salida multicanal y alto índice de aislamiento en un espacio limitado, lo que lo convierte en un componente clave para mejorar la densidad de potencia, la seguridad y la confiabilidad general del sistema.

Parámetros clave de rendimiento del moldeado por inserción :

| Category | Specific Parameters | Test Standard |

| Conductive Material | T2 copper (nickel/tin plated), High-purity aluminum (AL1000 series), Copper-aluminum composite | ASTM B209 / GB/T 5585.1 |

| Rated Voltage | Max. working voltage: DC 1500V / AC 1000V | IEC 60947 |

| Current-Carrying Capacity | Continuous current 250A – 5000A (section-optimized), Peak current ≥ 1.5x rated value, Temp. rise ≤ 40K (@25℃) | Enterprise standard / Thermal simulation |

| Insulation Performance | Withstand voltage ≥ 3000V AC (50Hz), Protection class IP67, Comparative Tracking Index CTI ≥ 600V | ISO 20653 / UL 746 |

| Structural Design | Integrated multi-branch topology, with mounting base and anti-loosening features, supports bolted/laser welding | Real-cabinet vibration test (IEC 60068-2-6) |

| Connection Method | Bolted connection (torque accuracy ±0.5N·m, sizes M6-M16), Optional laser welding (penetration ≥0.5mm) | IEC 60947 |

| Lightweight Benefit |

Aluminum solution weight reduction ≥30% vs. equivalent copper, Cu-Al composite reduction ≥35%

|

Real-cabinet comparison |

| Step | Core Process | Key Technical Points | Output Standard |

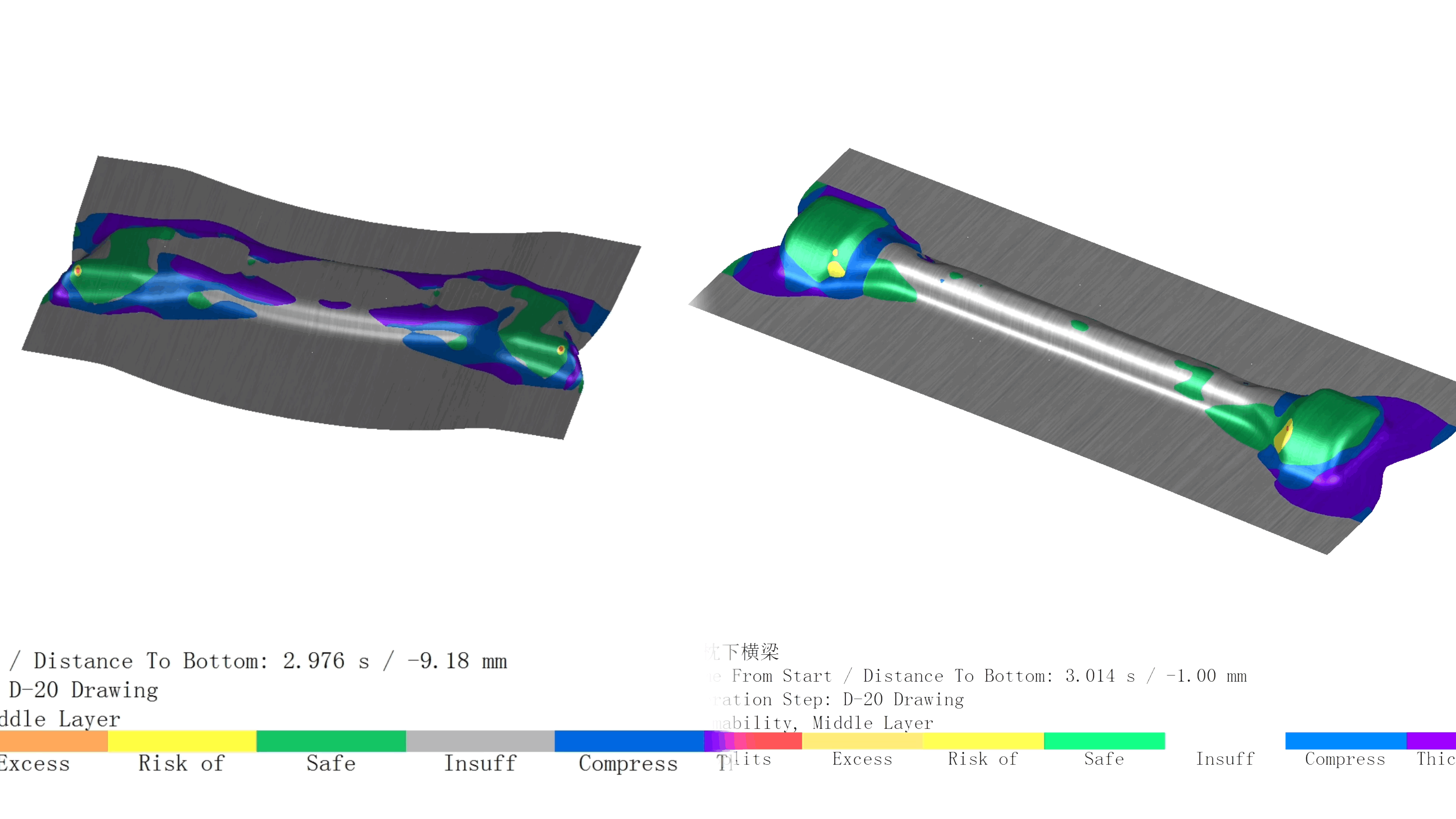

| 1 | 3D Design & Simulation | Electrical topology & thermal simulation, Mold CAE flow analysis | Current, temp. rise, insulation meet design specs |

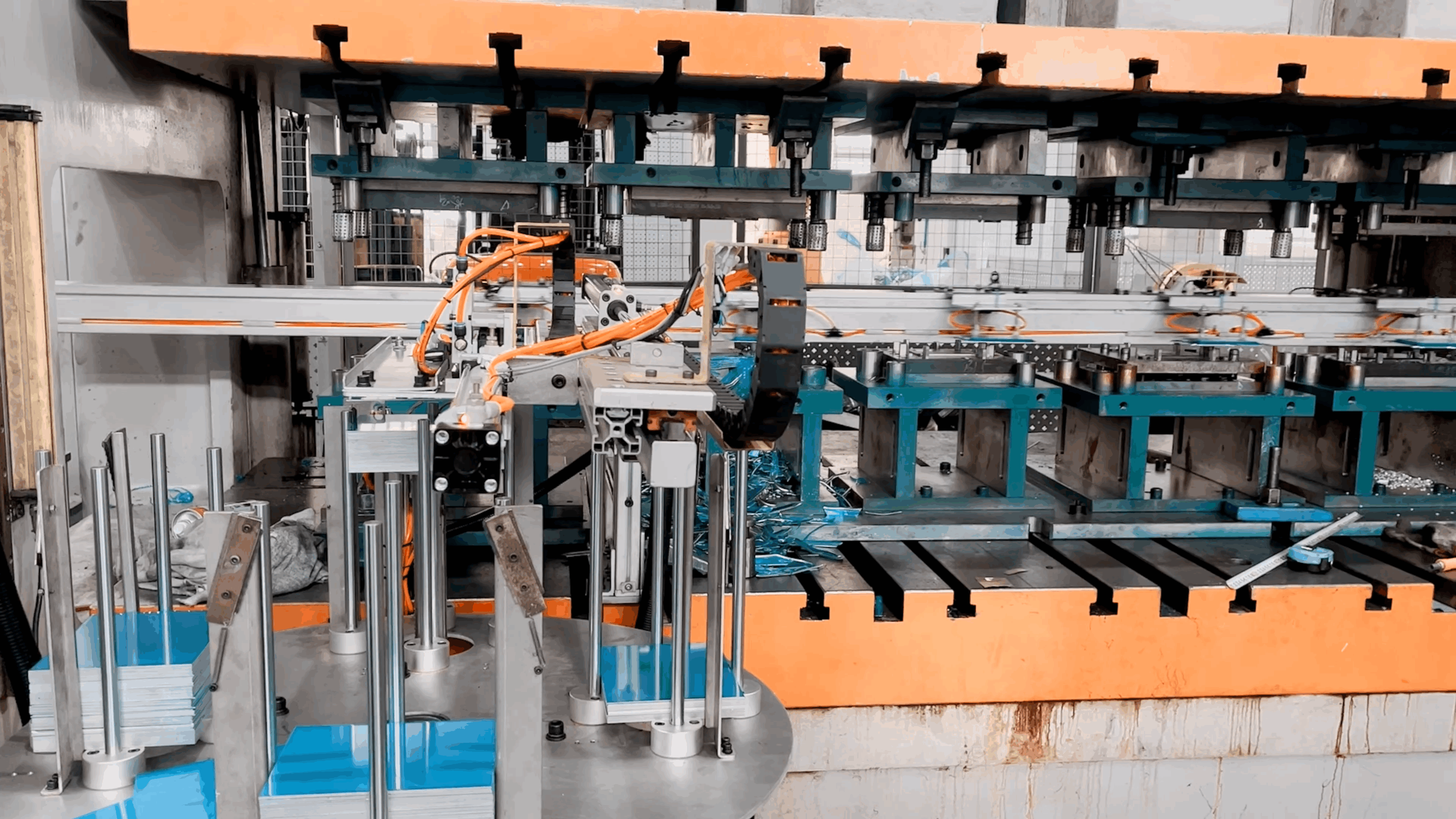

| 2 | Precision Stamping & Bending | Multi-station progressive die, Variable cross-section, Precision bending | Dimensional tolerance ±0.1mm, Burr/crack free |

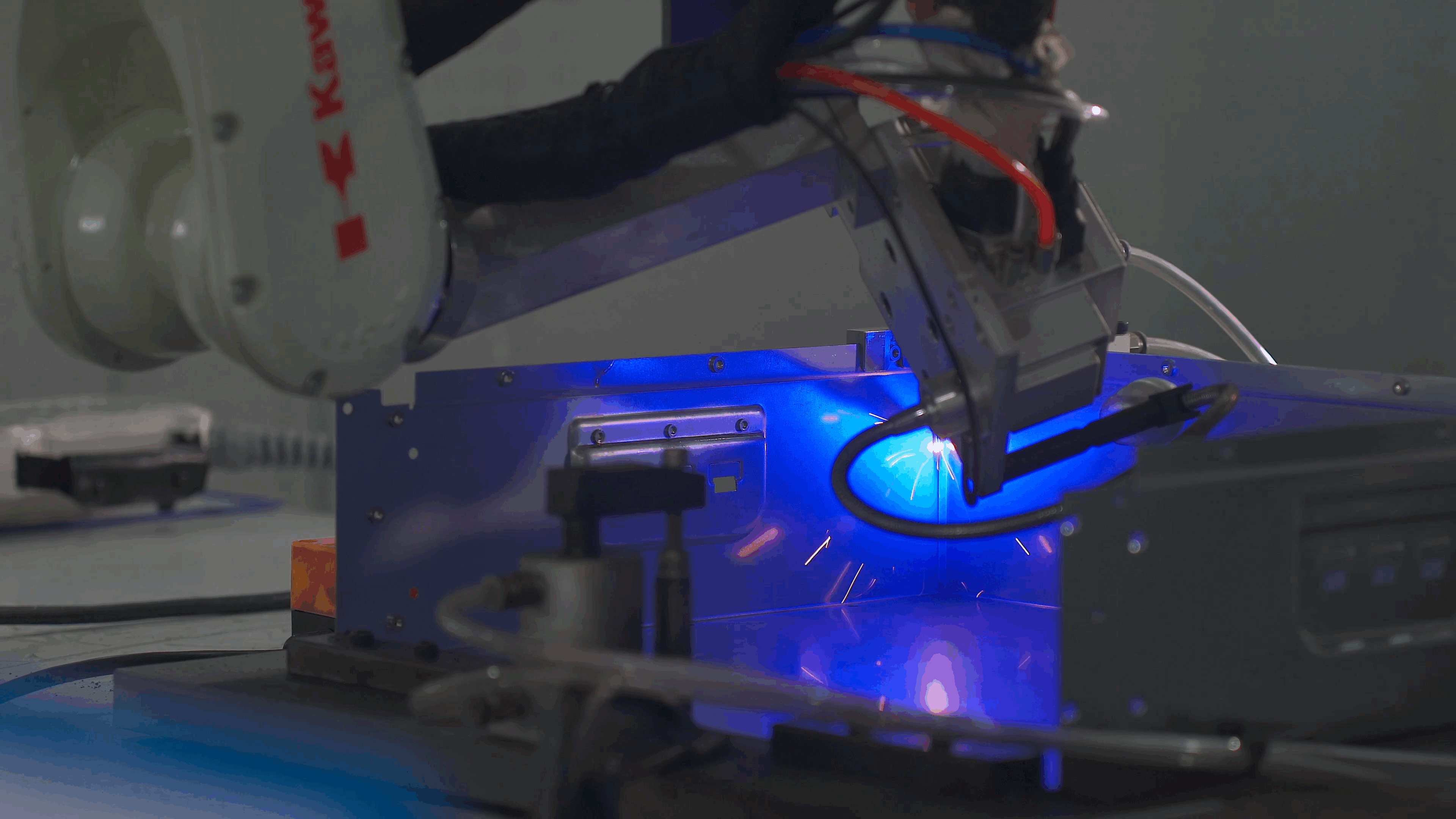

| 3 | Connection & Pre-assembly | Laser welding/Bolt pre-tightening, Insert nut pressing | Connection resistance deviation ≤3%, False weld rate<0.1% |

| 4 | Insert Molding | PPS/PA material, Precise mold temp. control, Retractable supports | Insulation layer free of voids/sink marks, Withstand voltage ≥3000V AC |

| 5 | Full Performance Test | Loop resistance, Partial discharge, Temp. rise cycle, Salt spray test | Defect rate ≤0.1%, Full MES data traceability |

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.