Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Modelo: Airbag System

Marca: htd

Lugar de origen: PORCELANA

Posicionamiento del producto:

El recipiente inflador HTD es el componente estructural y de contención de alta presión central dentro de un sistema de bolsas de aire para automóviles. Al actuar como "barrera de seguridad" del módulo de la bolsa de aire, debe resistir el calor intenso y el impulso de alta presión generado por el inflador en milisegundos, al tiempo que garantiza que la fuerza explosiva se canalice de manera precisa y controlable hacia el cojín de la bolsa de aire. Utilizando aleaciones/plásticos de ingeniería de alta resistencia y procesos de moldeo/formación de insertos de precisión, logra el equilibrio perfecto entre integridad estructural, sellado confiable y liberación de presión precisa en condiciones extremas, lo que lo convierte en un componente de seguridad fundamental para proteger la vida de los ocupantes.

Parámetros clave de rendimiento del estampado :

| Category | Specific Parameters | Test Standard |

| Primary Material | High-strength aluminum alloy (e.g., A356), Stainless steel, Reinforced engineering plastic (PPS/PA66-GF50) | Customer-specified / Material certification standard |

| Pressure Resistance | Static burst pressure ≥ 35 MPa; Dynamic impact resistance ≥ 150% of standard requirement | ISO 12097 / Customer DV testing |

| Sealing Grade | Helium leak rate ≤ 1×10⁻⁷ mbar·L/s, meeting lifetime sealing requirements | Enterprise standard / Helium mass spectrometry leak test |

| Operating Temperature | -40℃ ~ +110℃ (long-term), Peak temperature resistance ≥ 170℃ (short-term) | ISO 16750 |

| Structural Design | Integrated mounting flange and locating features, with internal metal reinforcement inserts, fool-proof design | 3D dimensional report / Fixture validation |

| Process Characteristics | Precision die casting/injection molding, internal cavity surface roughness Ra ≤ 1.6μm, Cleanliness level ≤ mg | VDA 19 / ISO 16232 |

| Safety Compliance | Complies with IMDS declaration requirements, meets OEM material and process specifications | Supports PPAP submission |

| Step | Core Process | Key Technical Points | Output Standard |

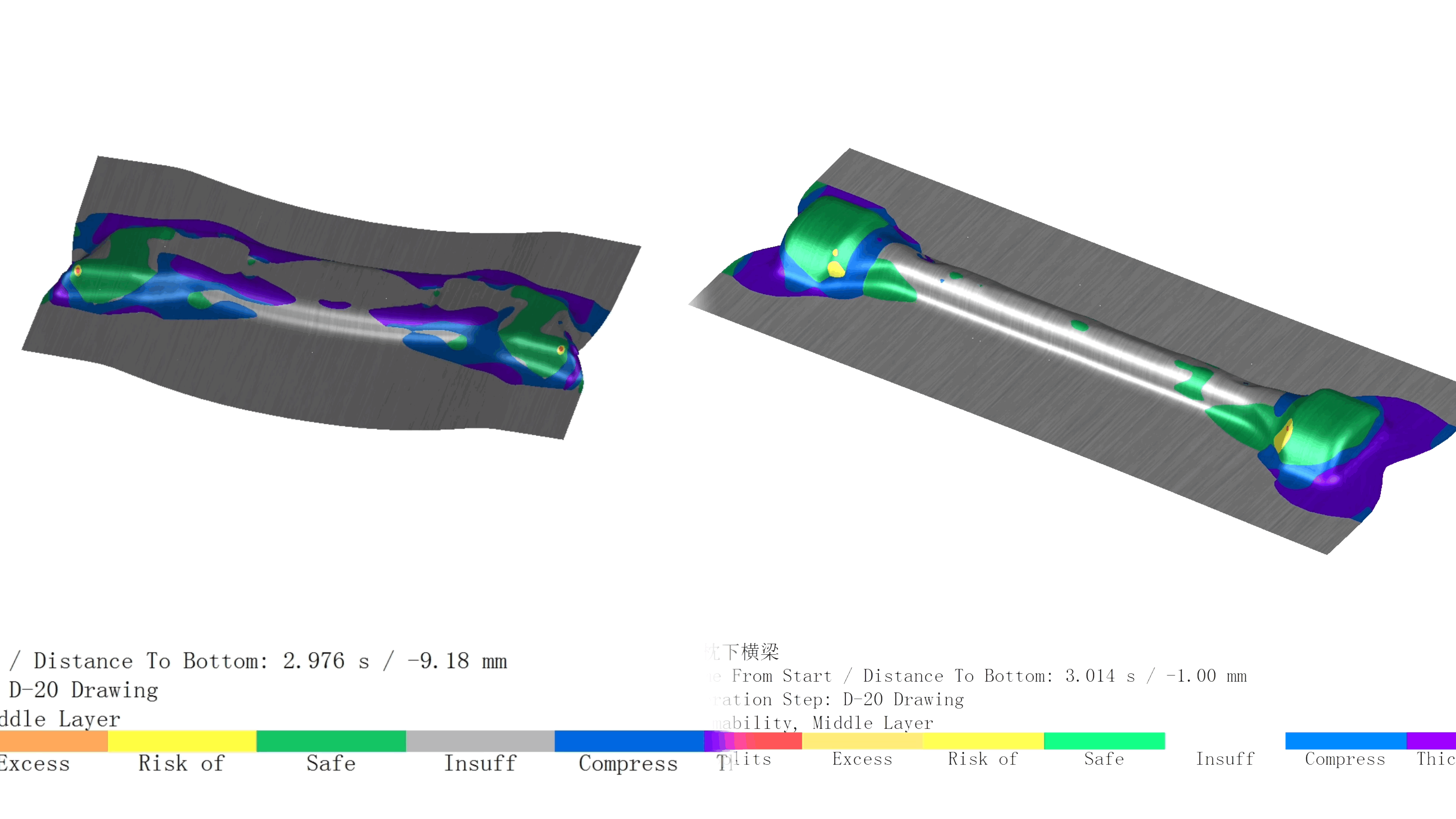

| 1 | Design & Simulation Validation | Static/Dynamic CAE, Mold flow & Tolerance analysis | Simulation report approved, design frozen |

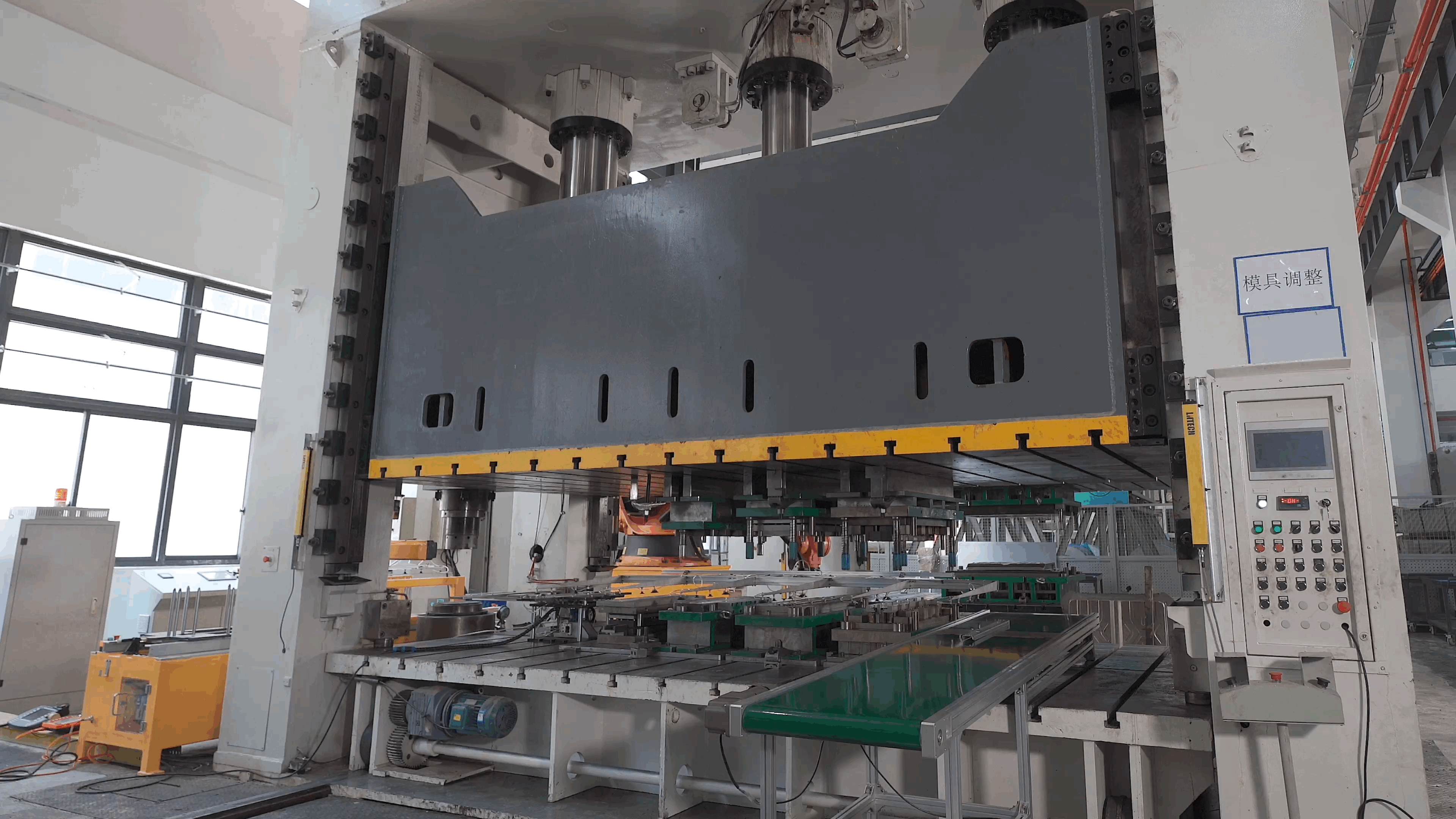

| 2 | Precision Forming | HPDC/Injection molding, precise mold temp. control, vacuum degassing | Casting/molding free of cold shuts/porosity, dimensions OK |

| 3 | Precision Machining & Cleaning | CNC machining of critical features, multi-stage ultrasonic cleaning + vacuum drying | Dimensional CPK≥1.67, reliable connection points |

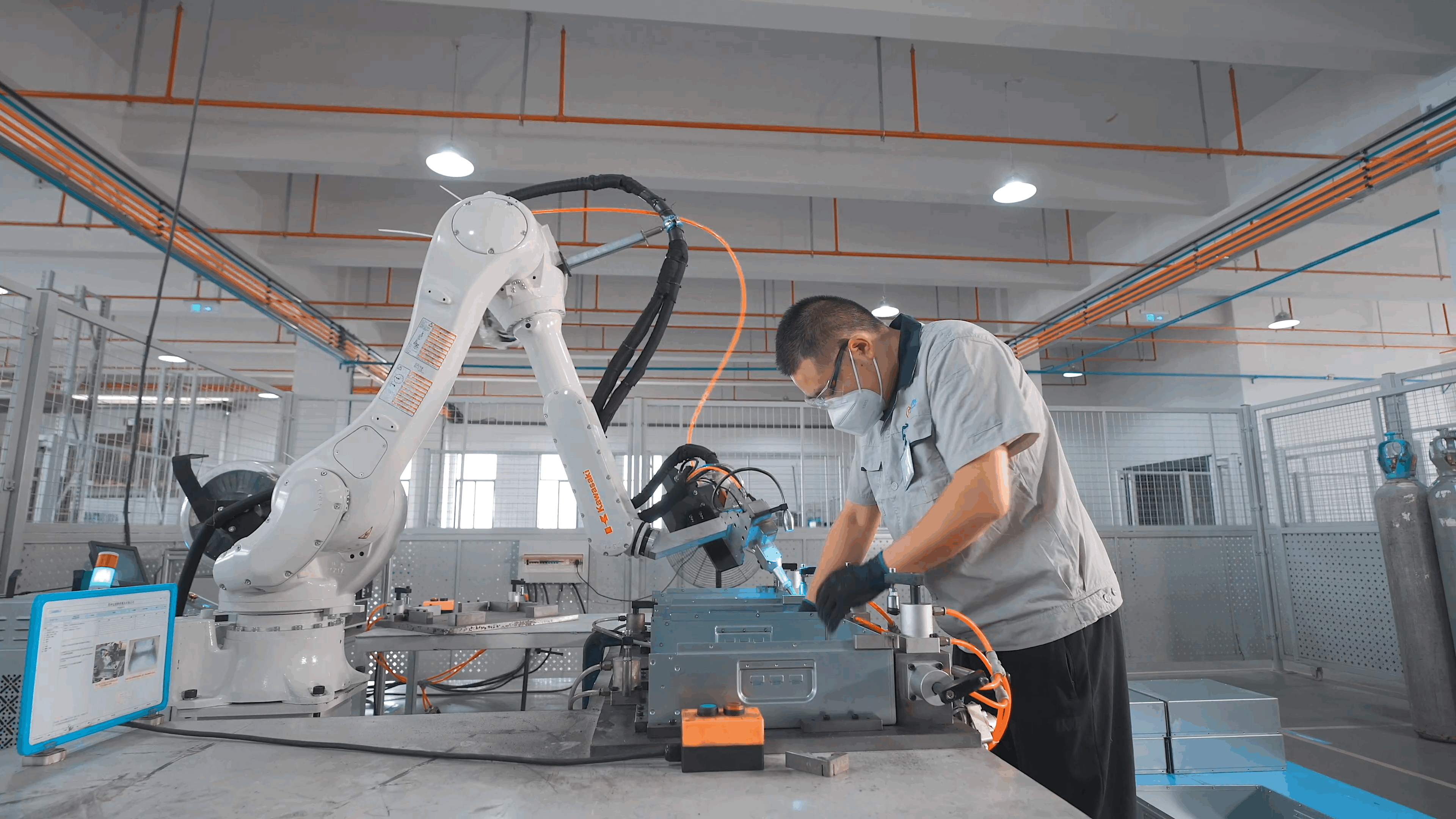

| 4 | Welding & Sealing Assembly | Laser welding (seam) or precision press-fitting (seal) | 100% helium leak test pass, weld NDT pass |

| 5 | Full Performance Test & Traceability | Burst pressure test, seal test, 100% dimensional check, cleanliness verification | 100% tested, full process traceability per part |

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.